CHEESE RACK

The ripening is an essential and very delicate phase in the process of the product maturation.

It occurs in well-insulated places through modern machinery for the control of internal temperature. During this phase we make accurate analysis to guarantee the organoleptic qualitative standards typical of each product.

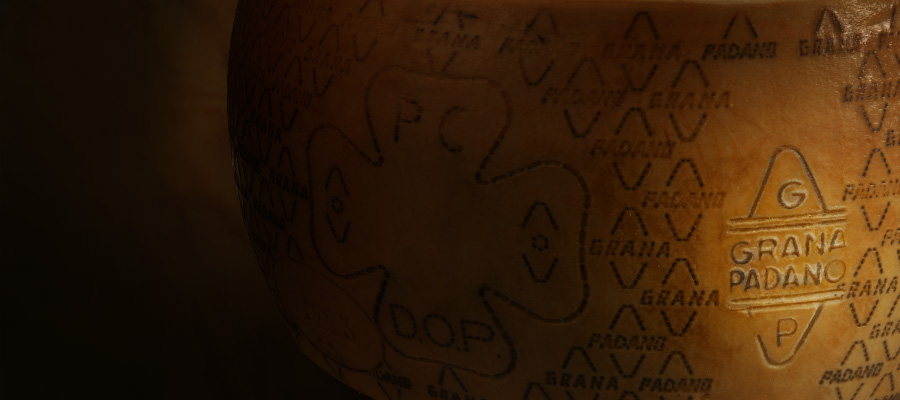

In base on cheese characteristics, each shape follows different phases of maturation. They rest on long wooden axes for several months and are constantly cured, cleaned and turned in order to allow the desired dryness and the creation of rind.

PHASES AND PLACES

The phases are constantly monitored by sector experts specialized in such operations during all the phases of maturation through strict controls to guarantee the qualitative standards specific for each product.

The available plants, in Villa Poma in province of Mantua, with 45,000 shapes, and in Bari with a surface of over 2,000 sq.m,, allow us through air-conditioning cellars and refrigerators to store, mature and ripen the cheese according to the different product needs.

For such procedures, our plants have robot machines, brushing machine and turning machine able to run on the entire area through proper predisposed rails facilitating the different operation during the ripening phase.

PACKING

The company Angiuli has the task with modern machines to cut the cheese and vacuum-pack it in order to exalt the product on trade counters and to guarantee a wide range of shapes in line with its own public.

For each product we have different typologies of packing in this way we can fully satisfy each consumer’s and producing company’s needs.

The cheese, from its storing till to the selling, are constantly followed by qualified personnel, who verify each phases to guarantee the maximum quality and hygiene, thus adhering to the strict system for prevention of hygienic-sanitary risks.